When the procurement team at a Nairobi-based education nonprofit received their first shipment of custom exercise books, the disappointment was palpable. “The colors were wrong, the binding was already failing, and the paper quality was nothing like the sample,” the director told me. “We lost $8,000 and, more importantly, the trust of the schools we serve.”

This costly mistake could have been avoided with the right questions upfront. After a decade of helping organizations navigate OEM partnerships for educational materials, we’ve identified the five questions that separate successful collaborations from expensive lessons.

The High Stakes of OEM Partner Selection

Choosing the wrong fornecedor de cadernos de exercícios doesn’t just waste money – it damages your reputation with end users. Students deserve quality materials, and your brand deserves partners who understand that.

The 5 Critical Questions You Must Ask

1. “Can You Provide Detailed Documentation of Your Quality Control Process?”

Why This Matters: Anyone can claim quality, but proven systems prevent disasters.

Look For:

Multi-stage inspection reports from raw materials to finished goods

Paper testing certifications for weight, opacity, and durability

Binding strength tests specific to your climate conditions

Color matching documentation for brand consistency

The Colorfly Standard: We provide clients with detailed QC checklists showing 14 distinct quality verification points, from paper moisture content testing to stitch-per-inch counts on bound notebooks.

2. “What Is Your True Production Capacity and Lead Time?”

Why This Matters: Suppliers often promise what they can’t deliver.

Look Beyond the Numbers:

Ask about peak season capacity versus normal operations

Request production line photos and facility documentation

Verify raw material sourcing reliability

Understand their logística de transporte and experience with your region

Real Example: When a sudden government tender required 200,000 notebooks in 30 days, our Colorfly production team leveraged relationships with paper mills and optimized our manufacturing schedule to deliver ahead of deadline.

3. “Can You Show Me Examples of Similar Custom Projects?”

Why This Matters: Experience with your specific needs prevents rookie mistakes.

Evaluate:

Project portfolios with your complexity level

Problem-solving examples when challenges emerged

Client references you can actually contact

Innovation examples beyond basic printing

4. “How Do You Handle Samples and Prototypes?”

Why This Matters: The sampling process reveals everything about a supplier’s attention to detail.

Warning Signs:

No formal sampling process

Charges for essential samples

Slow sample turnaround

Inconsistent sample versus production quality

The Right Approach: We operate a dedicated sample room where clients can test materials, review color matches, and verify specifications before production begins.

5. “What Happens When Something Goes Wrong?”

Why This Matters: Problems will occur – the response defines the partnership.

Critical Elements:

Clear communication protocols for issue escalation

Documented resolution processes with timelines

Quality failure compensation policies

Continuous improvement commitments

The Cost of Not Asking: A Cautionary Tale

A West African ministry of education learned this lesson painfully. They awarded a large tender to the lowest bidder without asking about climate adaptation. The result? 50,000 notebooks warped in humidity, ink smeared in heat, and covers detached during normal use.

“The financial loss was significant,” the procurement officer shared, “but the disruption to students’ education was unforgivable. Now we partner with Colorfly because they anticipated these environmental factors we hadn’t even considered.”

Your OEM Partner Evaluation Checklist

Documentation Verification:

Quality control certificates and processes

Environmental compliance documentation

Material sourcing and sustainability proofs

Production capacity and scheduling details

Sample Assessment:

Physical sample matches your specifications

Materials perform under your usage conditions

Custom elements meet brand standards

Packaging survives your distribution chain

Partnership Evaluation:

Communication responsiveness and clarity

Problem-solving approach and creativity

Cultural understanding of your market

Long-term relationship potential

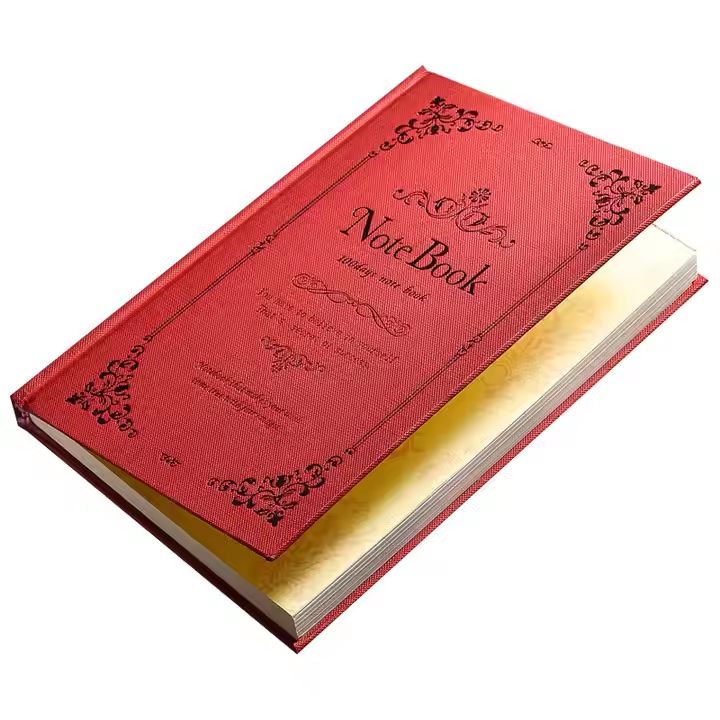

The Colorfly Difference: Partnership Beyond Production

What separates true OEM partners from simple suppliers is the willingness to invest in your success. When an East African publisher needed specialized notebooks for a new curriculum, we didn’t just manufacture – we collaborated:

Redesigned the binding to withstand frequent page-turning

Developed custom paper that worked with both pen and pencil

Created specialized packaging for rural distribution

Provided teacher training materials on using the notebooks effectively

“The partnership felt like having an extension of our own team,” the publisher noted. “They anticipated needs we hadn’t even articulated yet.”

Your Next Steps Toward the Right Partnership

Selecting an OEM partner for exercise books requires moving beyond price comparisons to value assessment. The right partner becomes an strategic asset; the wrong one a recurring headache.

Ready to evaluate partners with confidence?

We’ve created a detailed supplier evaluation toolkit based on our experience with hundreds of successful educational procurement projects.

[Download Our OEM Partner Evaluation Checklist]